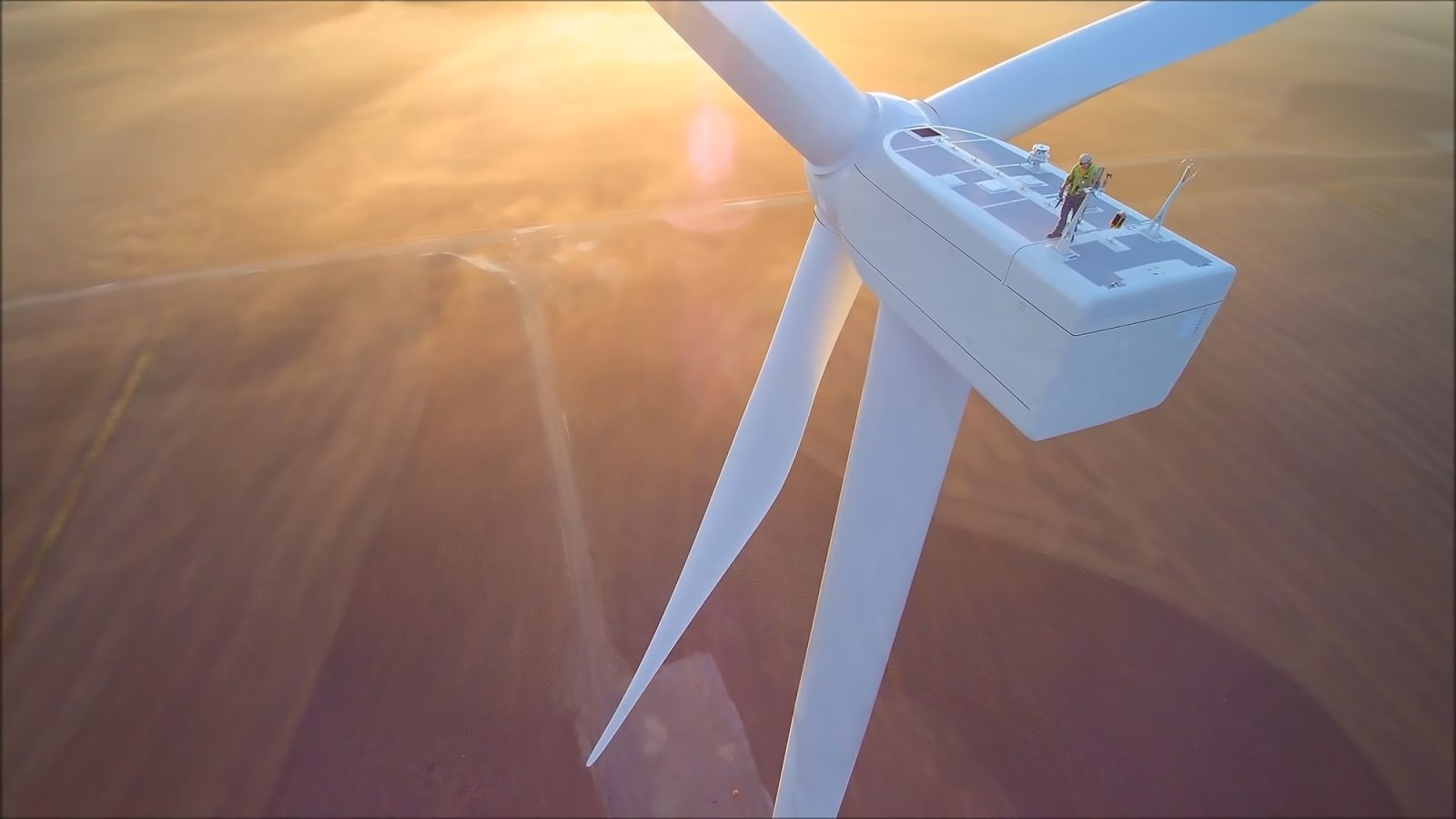

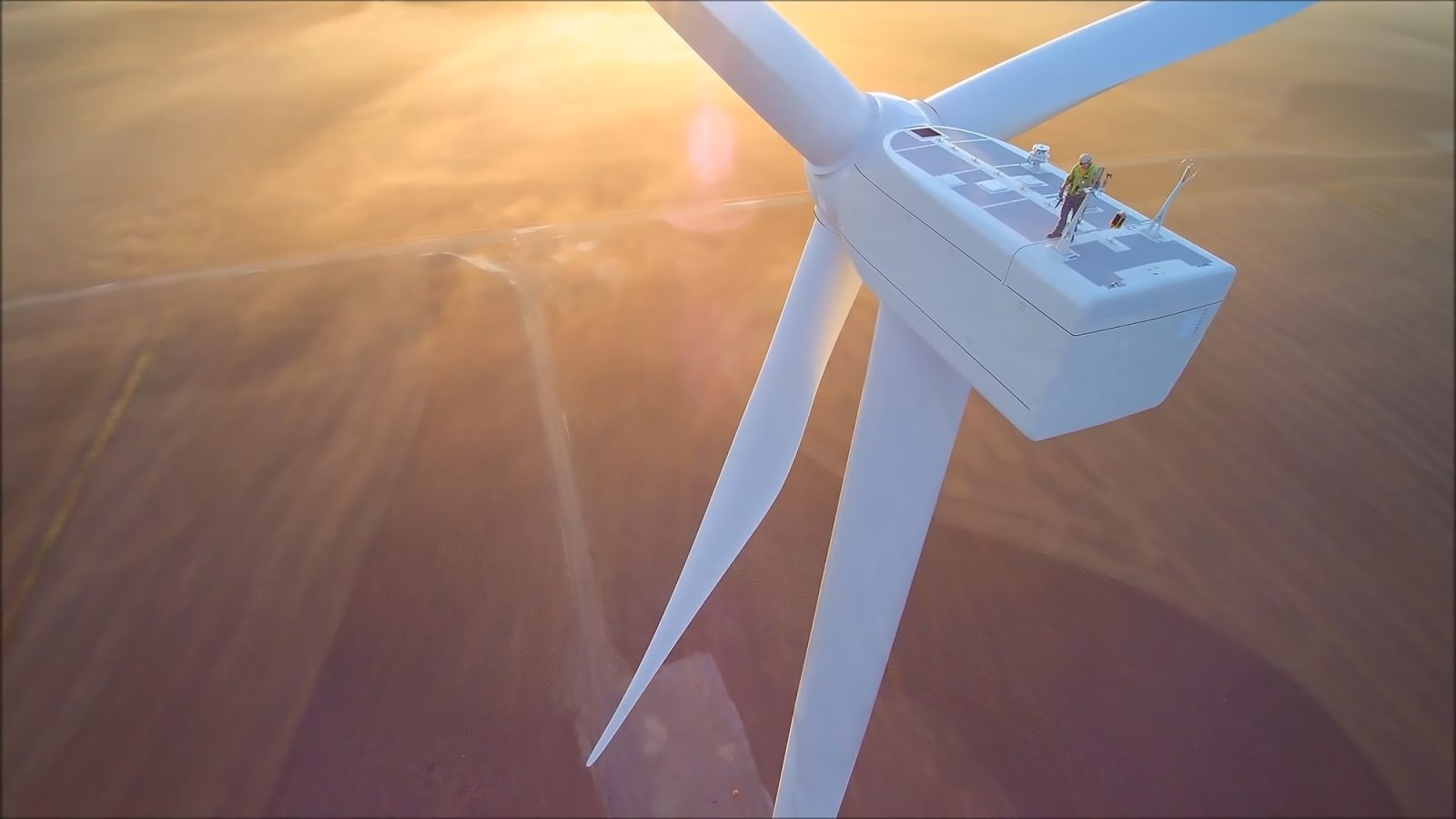

Wind Power

BrushBoxx supplies brush systems for high-efficiency energy generators such as wind turbines. The focus is on optimizing energy yield by minimizing maintenance and increasing system reliability. Our solutions are the result of many years of practical experience combined with simulated application tests. The use of resistant materials for desert climates to maritime locations ensures maximum availability.

Brush-based sealing concepts for maximum performance

With the help of flexible brush strips, the necessary sealing requirement can be achieved. Thanks to a design-to-cost development, we find the best result between tightness and price. The use of assembly-optimized brush bodies brings further cost savings. Another focus is on the required service life and thus the required wear resistance.

Sealing solutions as individual as your wind turbine

Our pressure-resistant sealing brushes cover areas up to 4000 Pa and thus protect against sand, dust, rain, snow and gushing water. Furthermore, the penetration of insects, bats and birds can be reliably prevented. Also the

The encapsulation of lubrication areas on blade bearings and azimuth bearings can also be ensured.

Diverter brushes for trouble-free operation of wind turbines

Due to their potential equalization, conductive brushes in small dimensions offer fast grounding coupled with low installation effort.

Furthermore, there are studies in which conductive brushes serve as current collectors in lightning protection systems.

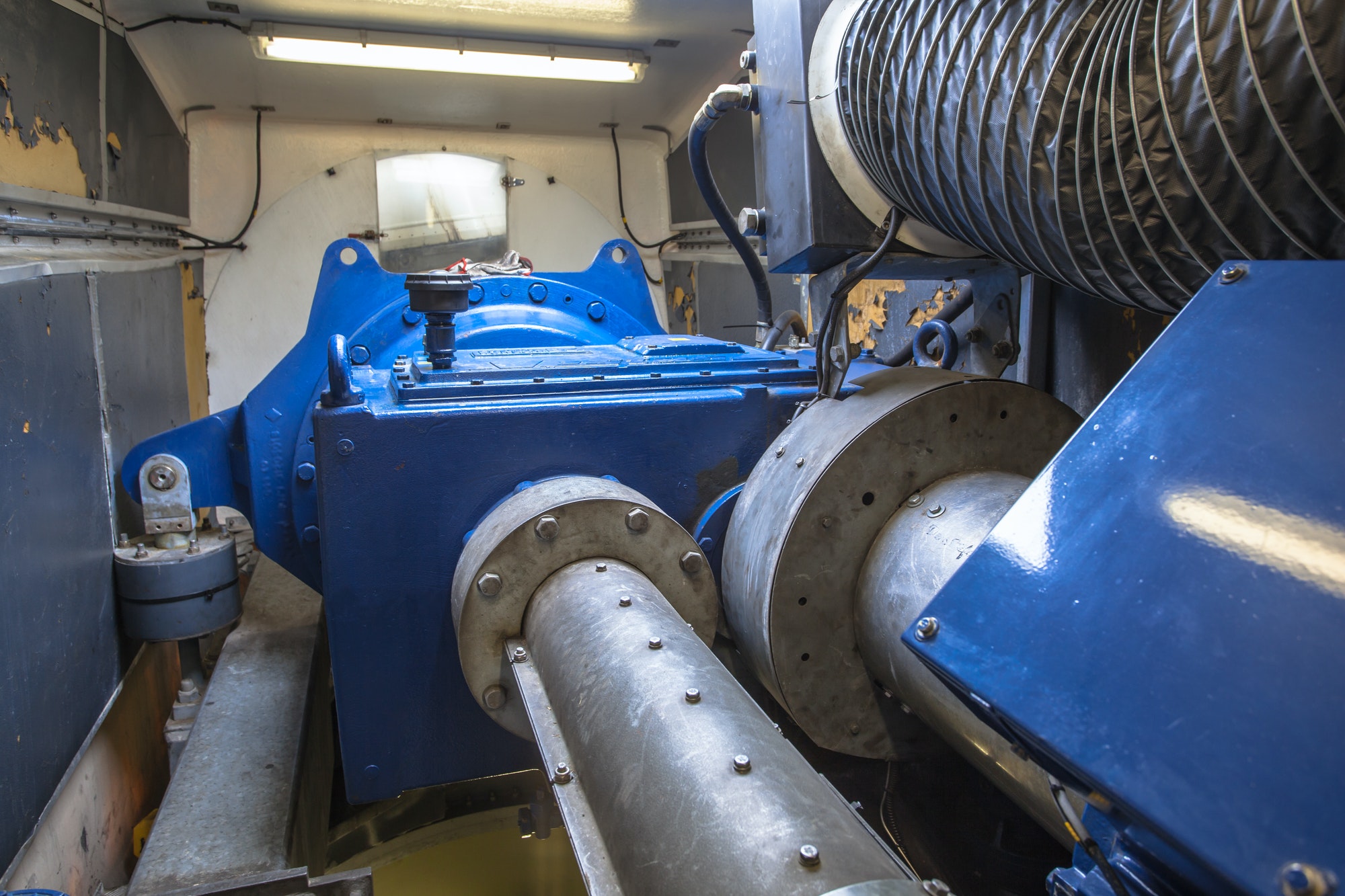

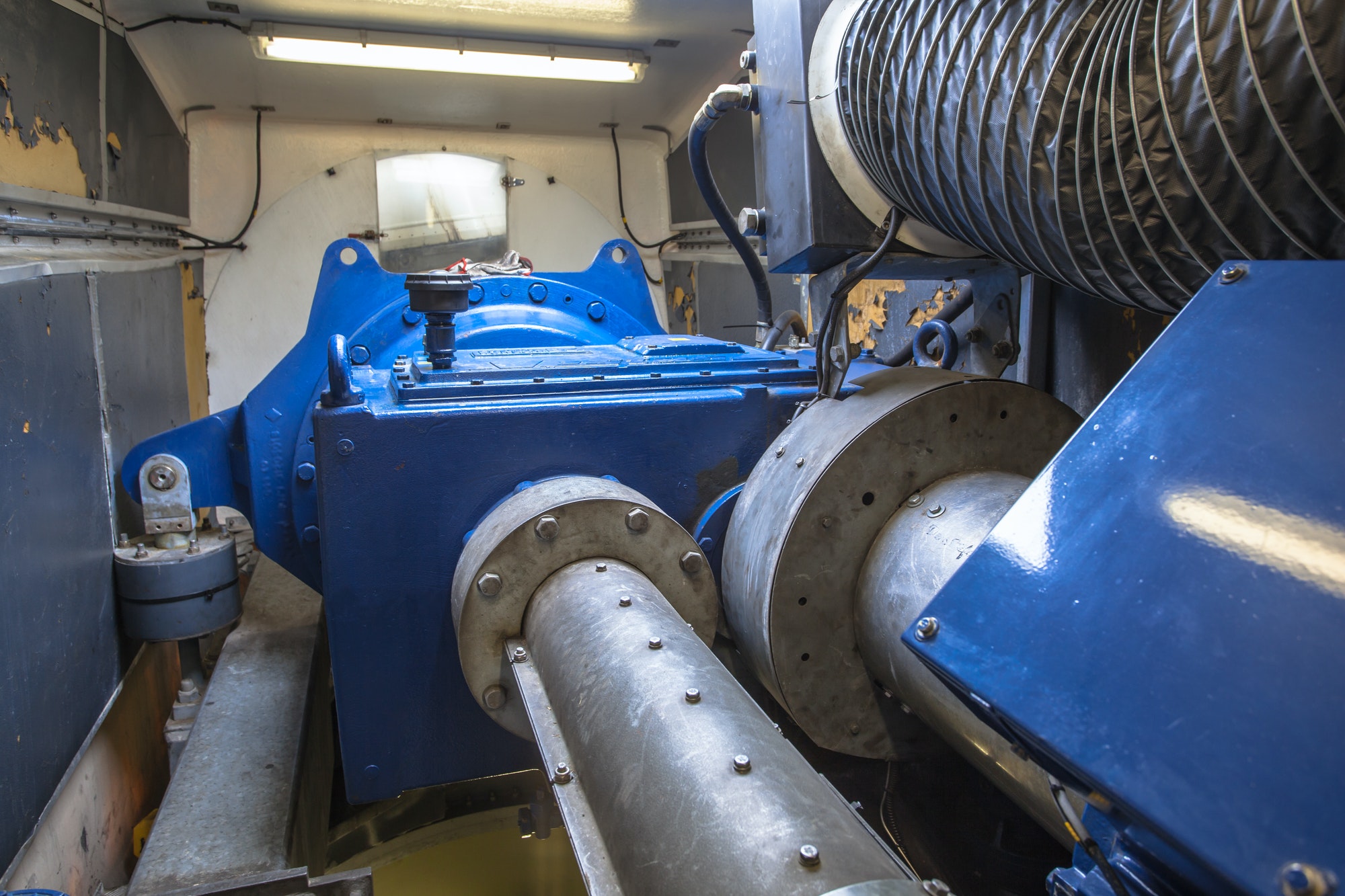

Test benches for validation under realistic conditions

On internal test rigs, we are able to examine the installation situation with regard to wear and pressure resistance. Under time-lapse conditions, statements can be made about the achievable service life and interactions with friction partners.

Your Contact

Peter Halm

Head of Business Area Agricultural Machinery and Wind Power

peter.halm (at) brushboxx.com

+49 1515 0552328